Cas: N.A

News

The Professional manufacturer of Silicones、 Silanes 、 Silicone Additives & Polymers

Feb. 12, 2026

Feb. 12, 2026

Methyltrichlorosilane is a crucial compound in various industrial applications, especially in silicone production. However, many people wonder how methyltrichlorosilane differs from alkoxysilanes. These differences are important for selecting the right material for your needs. For instance, understanding their reactivity and bonding properties can impact the final product's performance.

This article will explore how these two compounds serve different purposes in manufacturing. We will also discuss their unique applications and characteristics. This knowledge is vital for manufacturers and suppliers alike.

Methyltrichlorosilane is primarily used for producing high-purity silicon. In contrast, alkoxysilanes are versatile compounds commonly used in adhesives, coatings, and sealants.

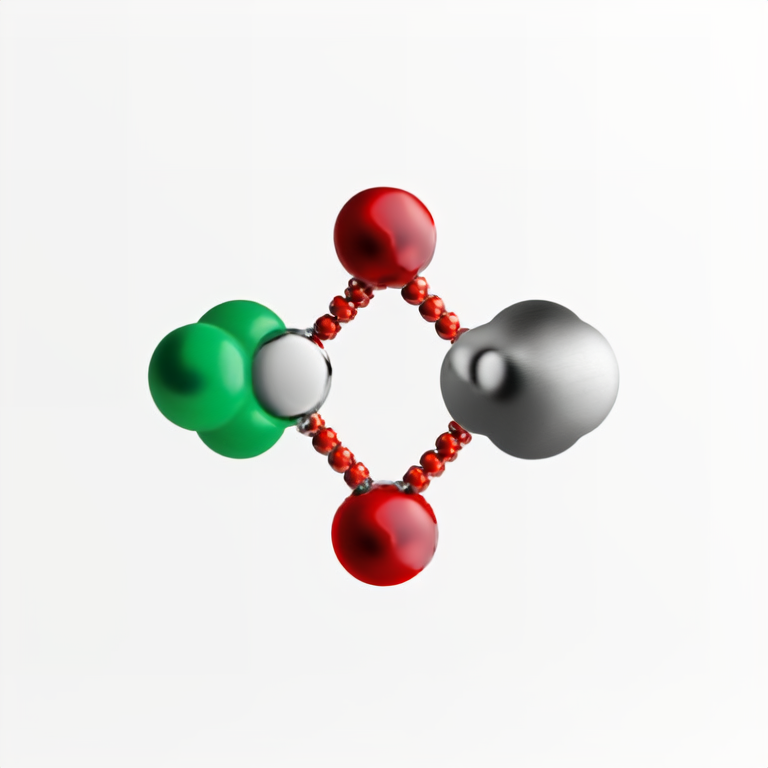

Methyltrichlorosilane has three chlorine atoms and one methyl group bonded to silicon. In comparison, alkoxysilanes contain an alkoxy group, which provides different reactivity traits.

Methyltrichlorosilane is highly reactive due to its chlorine atoms, making it effective for reactions that require bonding with silicon. Alkoxysilanes are less reactive, suitable for moisture-curing applications.

Methyltrichlorosilane is mainly used in the semiconductor and photovoltaic industries. Alkoxysilanes, on the other hand, are found in coatings, sealants, and adhesives.

Methyltrichlorosilane is less stable when exposed to moisture compared to alkoxysilanes. This factor affects their storage and handling procedures.

Generally, methyltrichlorosilane is pricier than alkoxysilanes due to its manufacturing process and demand in high-tech applications.

Methyltrichlorosilane poses higher toxicity concerns compared to alkoxysilanes. Therefore, adequate safety measures must be in place when handling.

In conclusion, understanding the application differences between methyltrichlorosilane and alkoxysilanes is vital for selecting the right material for various industries. Methyltrichlorosilane primarily serves high-purity silicon production. Meanwhile, alkoxysilanes have broader applications, especially in bonding and sealing. Making informed decisions can significantly enhance product quality and operational efficiency.

Q: What is methyltrichlorosilane used for?

A: Methyltrichlorosilane is primarily used in producing high-purity silicon for semiconductors.

Q: Are alkoxysilanes safe to use?

A: Generally, alkoxysilanes are considered safer than methyltrichlorosilane, but safety protocols should always be followed.

Q: How do I handle methyltrichlorosilane?

A: It should be handled in well-ventilated areas with appropriate protective gear due to its toxic nature.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...