Cas: N.A

News

The Professional manufacturer of Silicones、 Silanes 、 Silicone Additives & Polymers

Feb. 09, 2026

Feb. 09, 2026

Phenyltrimethoxysilane (PTMS), with a CAS number of 2996-92-1, is a high-performance organosilicon intermediate that combines both organic functional groups and inorganic silicon-based properties. Its unique molecular structure endows it with excellent heat resistance, reactivity, and compatibility. It is widely used in various high-end industrial fields such as organosilicon synthesis, material modification, and surface treatment, serving as a core additive to promote the upgrading of material performance. With stable quality and diverse application scenarios, it has gained extensive recognition in industries such as chemical engineering and new materials.

Ⅰ. Unique molecular structure lays the foundation for core advantages

The molecular structure of phenyltrimethoxysilane precisely combines the dual characteristics of organic phenyl groups and inorganic siloxy groups, providing a fundamental guarantee for its excellent performance. The core structural parameters are as follows:

Molecular formula: C₉H₁₄O₃Si

Molecular weight: 198.29

Molecular structure: With a silicon atom at the center, one end is connected to a phenyl group (C₆H₅−), and the other end is connected to three methoxy groups (−OCH₃), forming a unique structure of "organic functional group - silicon - inorganic functional group".

Analysis of structural advantages: The introduction of the phenyl group endows the product with excellent heat resistance, hydrophobicity, and organic compatibility, enabling it to perfectly integrate with organic materials such as resins and rubbers; The three methoxy groups provide strong reactivity. Under appropriate conditions, they can be hydrolyzed to form silanol groups, which can easily form stable bonds with inorganic materials such as glass, metals, and inorganic fillers, achieving efficient "bridging" between organic and inorganic materials. This is also the core reason for its wide application in modification across multiple fields.

Ⅱ. Excellent Core Performance, Adapting to High-End Application Requirements

Thanks to its unique molecular structure, phenyltrimethoxysilane exhibits diverse and excellent properties, combining stability and functionality, which can meet the high-end application demands of different industries. Its core properties are as follows:

Excellent heat resistance and high-temperature resistance: The conjugated structure of the phenyl group effectively enhances the thermal stability of the molecule. Compared with ordinary alkyl silanes, its heat resistance is significantly better. The long-term service temperature can be adapted to various high-temperature processing scenarios. It can also effectively improve the thermal stability of other silane products, preventing materials from yellowing, degradation, performance attenuation and other issues in high-temperature environments, thus meeting the needs of high-temperature processed polymers and high-end coating fields.

High reactivity and controllability: The trimethoxy group (-OCH₃) in the molecule has good hydrolysis activity. It can be slowly hydrolyzed to form silanol (-SiOH) under slightly acidic conditions or appropriate catalytic conditions, and then undergo a polycondensation reaction to form a stable siloxane network structure. At the same time, the rate of hydrolysis and polycondensation reactions can be regulated by temperature and pH value, which is suitable for the processing technologies of different materials and facilitates industrial mass application.

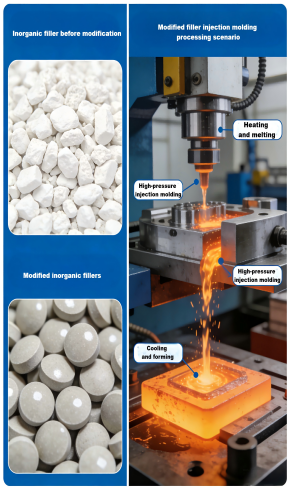

Good compatibility and dispersibility: It has the structural characteristics of both organic phenyl and inorganic silicon groups, enabling it to have good compatibility with organic materials such as epoxy resin, polyurethane and rubber, and to efficiently combine with inorganic materials such as glass, ceramics and inorganic powders. When used for filler modification, it can significantly improve the dispersibility of inorganic fillers in organic systems, avoid agglomeration, and optimize the processing performance of materials and the quality of finished products.

Excellent hydrophobic and corrosion resistance: The hydrophobic property of the phenyl group, combined with the siloxane protective layer formed after hydrolysis, can effectively improve the hydrophobic performance of the material surface and isolate moisture erosion. At the same time, it has good chemical corrosion resistance, can resist the erosion of most acid and alkali media (except strong acids and alkalis), prolong the service life of materials, and is suitable for application needs in humid and complex corrosive environments.

Stable physical and chemical properties: The product is a colorless and transparent liquid with a purity of over 98% (some specifications ≥99%), no obvious odor, a density of 1.062g/mL (25℃), a refractive index of n20/D 1.468, a boiling point of 233℃, a melting point of -25℃, and a flash point of 99°F. It is easily soluble in organic solvents such as ethanol and benzene, insoluble in water, convenient for storage and transportation, chemically stable at room temperature, and has a shelf life of 1-2 years (which can be extended if re-inspection is qualified).

III. Wide range of application fields, empowering innovation and development in multiple industries

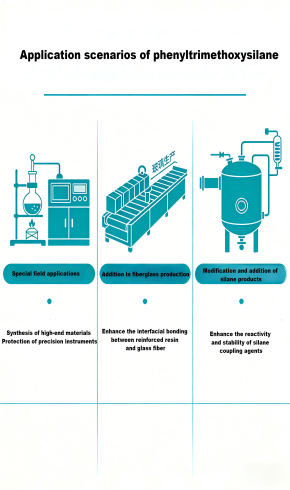

Phenyltrimethoxysilane, with its multiple excellent properties, is widely used as an organosilicon intermediate, modifier, and surface treatment agent in various fields such as organosilicon material synthesis, coatings and inks, composite materials, plastics and rubber, filler modification, automobile industry, electronics and semiconductors. Each application scenario is accompanied by practical application pictures to intuitively present its application value:

1. Field of silicone material synthesis - core raw materials, laying a solid foundation for quality

2. Field of surface treatment of inorganic fillers - modification to enhance efficiency and optimize processing performance

3. Coatings and Inks Field - Modification and Upgrading to Enhance Product Competitiveness

4. Plastic and Rubber Field – Performance Optimization to Expand Application Boundaries

5. Pigment dispersion field - uniform dispersion to improve color quality

6. Automotive and Electronics Industry - High-end Adaptation to Facilitate Quality Upgrades

7. Other Special Fields - Multiple Adaptations to Expand Application Value

IV. Quality Assurance, Collaborating to Create Value

The phenyltrimethoxysilane we produce strictly adheres to industry standards, adopts advanced production processes, and controls product quality throughout the entire process to ensure stable product purity, physical and chemical properties, with all indicators meeting the application requirements of industrial grade and high-end grade. The product packaging specifications are complete, available in 5L, 10L, 25L, 210L iron drums or 1000L IBC containers. Customized packaging can be provided according to customer needs. The sealing performance is excellent, which can effectively isolate moisture and light, facilitating storage and transportation. At the same time, we provide comprehensive after-sales service and technical support, customize exclusive solutions according to customer application scenarios, help customers optimize production processes, improve product quality, and reduce production costs.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...