If you are interested in our products or would like to learn more information, please contact us

|

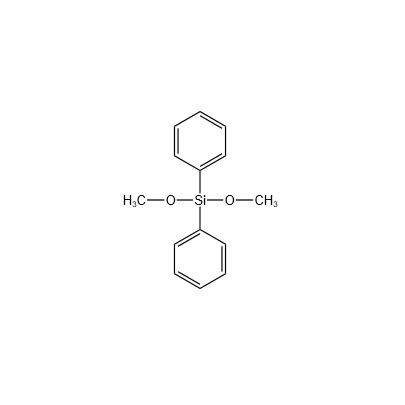

CAS号 CAS No. |

6843-66-9 |

|

分子式 Molecular Formula |

C14H16CO2Si |

|

分子量 Molecular Weight |

244.37 |

|

沸 点 Boiling Point |

286℃ |

|

闪 点 Flash Point |

157 ℃ |

|

外 观 Color and Appearance |

无色透明液体 Colorless transparent liquid |

|

密 度 Related Density |

1.08 g/mL |

|

折光率 Refractive Index |

1.5385 [n20/D] |

|

等规度 Isotactic degree |

≥95% |

|

拉伸强度 Tensile strength |

≥35 MPa |

|

热变形温度 Thermal distortion temperature |

120℃ |

|

含 量 Min. Purity |

Min 98% |

Application:

1.Propylene Polymerization Catalyst System

Application: Production of homopolymer polypropylene and block copolymer polypropylene, particularly suitable for high-rigidity, high-crystallinity polypropylene products.

Core Value: Enhances polymer isotacticity and stereoregularity, reduces atactic content, optimizes material processability and flow, and facilitates the production of high-performance products such as automotive bumpers, appliance housings, chemical pipelines, and packaging films.

2.Silicone Rubber and Fumed Silica Modification

Application: Production of silicone rubber (HTV, RTV), silicone sealants, and silicone adhesives; surface modification of fumed silica.

Core Value: Replaces hydroxy silicone oil, improves filler-matrix compatibility, reduces system viscosity, enhances mechanical properties and aging resistance, extends storage stability of compounded rubber, and reduces waste during production.

3.Raw Materials for Silicon-Based Material Synthesis

Silicone Resin Synthesis: Serves as an efficient cross-linking agent in the production of high-temperature resistant and weather-resistant silicone resins, improving hardness, adhesion, and high/low-temperature performance. Suitable for electronic encapsulants, high-temperature coatings, and aerospace composites.

Phenyl Silicone Oil / Silicone Rubber Synthesis: Serves as a key monomer, providing excellent high/low-temperature resistance (-60℃ to 300℃), radiation resistance, and aging stability. Used in high-end applications such as thermal management fluids for electronic components, aviation hydraulic oils, and medical device seals.

Packaging and Storage:

Shelf Life: 6 months. Packaged in 200L galvanized iron drums or customized packaging. Transported with moisture-proof and shock-resistant measures.

Storage: Keep sealed in a cool, dry place away from direct sunlight and high temperatures.

Chemical Precautions: May react with other substances. Conduct thorough testing and evaluation before use.

Handling: Wear appropriate protective equipment and follow safety protocols. Avoid skin/eye contact. In case of exposure, rinse immediately with copious water and seek medical advice promptly.

Special Note:

The instruction documents, technical parameters, operation guidelines and relevant data of this product are compiled in accordance with the principles of professionalism and integrity, based on the current scientific understanding and experimental conclusions.

Given that uncontrollable factors such as transportation and storage conditions, external environment, supporting facilities and user technical capabilities may lead to discrepancies between the product’s actual performance and nominal specifications, users shall independently evaluate the product’s adaptability to their application scenarios. Moreover, a comprehensive and full-scale experimental verification must be conducted prior to the official use of the product to confirm its compliance with user-specific requirements.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...