If you are interested in our products or would like to learn more information, please contact us

|

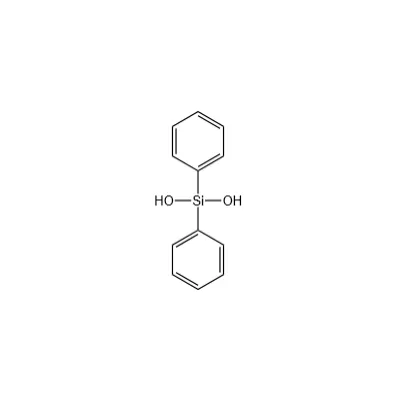

CAS号 CAS No. |

947-42-2 |

|

分子式 Molecular Formula |

C12H12O2Si |

|

分子量 Molecular Weight |

216.31 |

|

外 观 Color and Appearance |

白色针状或粉末晶体 White needle-like or powdered crystals |

|

水分 Water content |

≤0.1% |

|

含 量 Min. Purity |

Min 99% |

Application:

1. Silicone Resin Synthesis & Crosslinking

Application Scenarios: Production of high-temperature-resistant, weather-resistant and high-hardness silicone resins; Synthesis of electronic encapsulation resins, high-temperature coatings and matrix resins for aerospace composites.

Core Values: As a high-efficiency crosslinking agent, it undergoes condensation reaction with silanol groups on silicone resin molecular chains via hydroxyl groups to form a 3D network structure, enhancing resin hardness, adhesion, thermal resistance and chemical corrosion resistance. The introduction of phenyl groups boosts radiation resistance and yellowing resistance, making it ideal for high-end industrial coatings and electronic encapsulation scenarios.

2. Organosilicon Material Modification

Application Scenarios: Production of high-temperature vulcanized silicone rubber, room-temperature vulcanized silicone rubber, organosilicon sealants and silicone adhesives; Synthesis of phenyl silicone oils and special organosilicon products.

Core Values: As a structure regulator and modifier, it improves the tensile strength, tear strength and elastic recovery rate of silicone rubber, and enhances product aging resistance and thermal resistance. It optimizes the bonding performance and weather resistance of organosilicon sealants, suitable for electronic component sealing, aerospace sealing rings and high-end construction sealing applications.

3. Inorganic Filler Surface Modification

Application Scenarios: Organic modification of inorganic filler surfaces such as fumed silica, titanium dioxide, aluminum oxide and talcum powder; Optimization of filling systems for rubber, plastics and composites.

Core Values: The dihydroxy groups form stable chemical bonds with hydroxyl groups on filler surfaces, constructing an organic coating layer on the filler surface to improve the compatibility and dispersibility between fillers and organic matrices. It reduces the viscosity of composite systems, improves processing efficiency, and enhances the mechanical properties and aging resistance of products.

4. Special Material Synthesis Raw Material

Application Scenarios: Production of radiation-resistant materials, biocompatible organosilicon materials and high-end lubricating materials; Synthesis of electronic-grade thermal conductive composites.

Core Values: As a dedicated monomer raw material, it endows products with unique functional properties such as radiation resistance (withstanding 10⁶ Gy radiation dose), biological inertness and high thermal conductivity, expanding the application boundaries of materials in high-end fields including nuclear industry, medical devices and electronic information.

Packaging and Storage:

Shelf Life: 12months.

Packaged in double-layer PE plastic bags inside outer fiberboard drums. Transported with moisture-proof and shock-resistant measures.

Storage: Keep sealed in a cool, dry place away from direct sunlight and high temperatures.

Chemical Precautions: May react with other substances. Conduct thorough testing and evaluation before use.

Handling: Wear appropriate protective equipment and follow safety protocols. Avoid skin/eye contact. In case of exposure, rinse immediately with copious water and seek medical advice promptly.

Special Note

The above product descriptions, technical parameters, usage recommendations and related data are compiled based on current scientific knowledge and experimental data in accordance with the principles of professionalism and integrity. However, the actual performance of the product may vary due to uncontrollable factors such as transportation and storage conditions, external environments, supporting facilities and user technical capabilities. Users shall independently evaluate the product’s suitability for their intended application. Full experimental verification is required before use to confirm compliance with your specific requirements.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...