If you are interested in our products or would like to learn more information, please contact us

|

CAS号 CAS No. |

18407-48-2 |

|

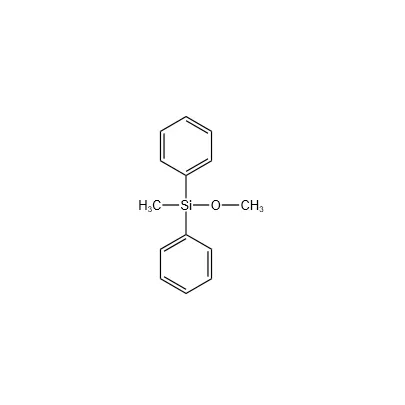

分子式 Molecular Formula |

C14H16OSi |

|

分子量 Molecular Weight |

228.37 |

|

沸 点 Boiling Point |

275℃ |

|

闪 点 Flash Point |

82℃ |

|

外 观 Color and Appearance |

无色透明液体 Colorless transparent liquid |

|

密 度 Related Density |

1.06 g/mL |

|

折光率 Refractive Index |

1.5315 (n20/D) |

|

含 量 Min. Purity |

Min 99% |

Application:

Product core characteristics:

• Overcoming Material Performance Challenges in Harsh Environments

This product delivers consistent performance and reliable resistance to extreme temperatures and aging, thanks to its exceptional purity (≥99.0%) and broad-temperature stability (-50 ℃ to 250 ℃). It streamlines processing control and ensures end-product reliability under demanding conditions.

• Enabling Polymer Material Design and Performance Enhancement

Featuring a unique dual-functional-group design, it precisely interacts with and regulates the molecular chain ends of silicone materials, making it an ideal choice for optimizing the structure of silicone resins and rubbers. It effectively raises the heat resistance limit to 300 ℃, improves anti-yellowing properties, and enhances processability as well as the flexibility and service life of finished products.

• Meeting Sustainable Supply Chain Requirements

The product complies with stringent global environmental regulations (e.g., REACH, RoHS) and adopts green manufacturing practices aimed at reducing environmental impact, helping you develop safer and more sustainable end products.

Application:

1. Polymer Material Modification

Glass Fiber Surface Treatment: Acts as a coupling agent to enhance compatibility between glass fibers and resins (e.g., epoxy, polyester), improving mechanical strength by over 30% in reinforced plastic laminates. Offers optimized heat resistance (long-term service up to 180 ℃) and moisture resistance, suitable for wind turbine blades, automotive parts, and electronic housings.

Plastic Modification: Improves dispersion of inorganic fillers (e.g., talc, calcium carbonate) in PP, PA, PC, etc., enhancing impact strength and aging resistance.

Rubber Modification: Serves as a crosslinking agent for RTV silicone rubber, improving tensile strength, tear strength, and extending temperature tolerance (–50 ℃ to 200 ℃). Ideal for construction sealants, electronic potting compounds, and medical silicone products.

2. Organosilicon Material Synthesis

Silicone Resins: Used in synthesizing heat-resistant methyl phenyl silicone resins, providing excellent electrical insulation and weather resistance for electronic component encapsulation and high-temperature coatings.

Specialty Silicone Oils: Enables production of branched methyl phenyl silicone oils with enhanced lubricity and radiation resistance for aerospace and precision machinery lubrication.

Silane Coupling Agents: Serves as an intermediate for synthesizing specialty coupling agents used in coatings, adhesives, and inks to improve substrate adhesion.

3. Fine Chemicals & Advanced Materials

Pharmaceutical/Cosmetics Intermediates: Functions as a silicon-based protecting group in drug synthesis or for producing highly compatible cosmetic additives (e.g., sunscreens, conditioners).

Optical Materials: Used in synthesizing high-refractive-index optical resins and lens coatings to improve light transmittance and scratch resistance.

Ceramic Matrix Composites: Acts as a ceramic precursor for high-temperature (above 800 ℃) ceramic matrix composites in defense, aerospace, and aircraft engine applications.

Packaging and Storage:

Product Shelf Life: 12 months

Packaging: Supplied in 200L iron drums or custom packaging (200L closed-head galvanized iron drums). Designed for moisture-proof and shock-resistant transport.

Storage: Keep container tightly sealed in a cool, dry place. Avoid direct sunlight and high-temperature environments.

Safety & Handling:

Due to its chemical nature, the product may react with other substances. Conduct thorough testing and evaluation before use.

Wear appropriate personal protective equipment (PPE) and follow relevant safety procedures during handling.

Avoid direct contact with skin and eyes. In case of contact, rinse immediately with plenty of water and seek medical attention promptly.

Special Note:

The product descriptions, technical specifications, usage recommendations, and related data provided above are compiled based on current scientific knowledge and experimental data, with professionalism and integrity. However, the actual performance of the product may vary due to uncontrollable factors such as transportation and storage conditions, external environments, supporting facilities, and user technical capabilities. Users must independently evaluate the suitability of the product for their intended applications. Before using the product, users should conduct sufficient testing to determine whether it meets their specific requirements.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...