If you are interested in our products or would like to learn more information, please contact us

|

CAS号 CAS No. |

546-45-2&77-63-4&34239-75-3 |

|

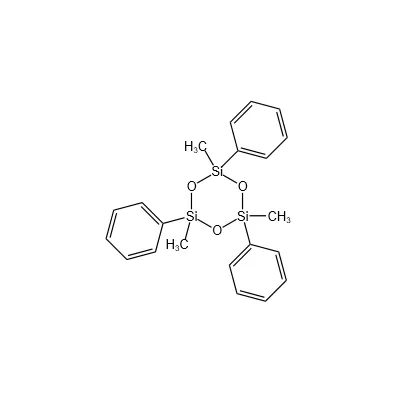

分子式 Molecular Formula |

[CH3(C6H5)SiO]m=3-5 |

|

沸 点 Boiling Point |

160-260,℃,0.13kpa |

|

闪 点 Flash Point |

>200°C |

|

外 观 Color and Appearance |

无色透明油状液体或有白色结晶 Colorless transparent oily liquid or white crystal |

|

折光率 refractive index |

1.54-1.55 (n20/D) |

|

粘度 viscosity |

50-300mm2/s (25℃) |

|

密 度 Related Density |

1.08 g/cm3 |

|

含 量 Min. Purity |

Min 98% |

Application:

Electronics & Aerospace

As a core raw material for high-end methylphenyl silicone rubber and silicone resin, it is used in encapsulation coatings for electronic components, adhesives for laminated materials, ablation-resistant coatings, etc. With excellent radiation resistance and high dielectric properties, it meets the material requirements for extreme environments in nuclear power equipment and aerospace applications.

Beauty & Daily Chemicals

It can serve as a key ingredient in skin care creams, lotions, lipsticks and sunscreen products, providing excellent hydrophobicity and skin feel improvement effects. It is also used in hair oils and conditioners to enhance product smoothness and stability.

Industrial Lubrication & Coatings

It is used as a lubricating oil additive to improve the high temperature resistance and anti-aging performance of oils. It is applied in preparing high-performance coatings to enhance the chemical corrosion resistance and weather resistance of coatings, meeting the protection needs of industrial equipment.

Medical & High-end Materials

It is used to produce medical-grade silicone rubber materials. Thanks to its biocompatibility and sterilization resistance, it is suitable for seals and catheters of medical devices. It can also be used as a plasticizer for optical materials to improve the light transmittance and stability of materials.

Product Shelf Life: 12 months.

Packed in 200L open-top blue steel drums or 25kg cardboard drums. Transport with moisture-proof and shockproof measures.

Storage: Keep containers tightly sealed and store in a cool, dry place away from direct sunlight and high temperatures.

Due to the chemical nature of the product, it may react with other substances. Therefore, adequate testing and evaluation should be conducted prior to use.

During use, appropriate personal protective equipment must be worn, and relevant safety operating procedures must be followed. Avoid direct contact with skin and eyes. In case of accidental contact, rinse immediately with plenty of water and seek prompt medical attention.

Special Notes:

The above product description, technical parameters, usage recommendations, and related data are prepared based on current scientific knowledge and experimental data, with a professional attitude and in good faith. However, the actual performance of the product may vary due to uncontrollable factors such as transportation and storage conditions, external environment, supporting facilities, and user technical capabilities. Users shall independently evaluate the suitability of the product for their intended application. Prior to using this product, users must conduct sufficient testing and verification to determine whether it meets their requirements.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...