If you are interested in our products or would like to learn more information, please contact us

Physical and chemical properties

| CAS No. | 556-67-2 |

| EINECS No. | 209-136-7 |

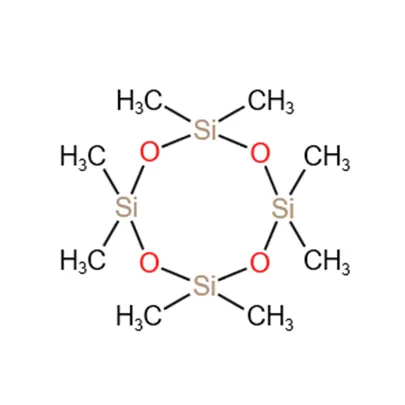

| Molecular Formula | C8H24O4Si4 |

| Molecular Weight | 296.62 |

| Boiling Point | 175~176°C |

| Flash Point | 60℃ |

| Color and Appearance | Clear colorless liquid |

| Related Density | 0.9558 |

| Refractive Index | 1.3968 [20°C] |

| Min. Purity | Min 99.0% |

Application

Octamethylcyclotetrasiloxane (D4) is a colorless, transparent or milky white liquid that is flammable and odorless. It is a compound obtained by separation and distillation of the product obtained by hydrolysis of dimethyldichlorosilane. It is an important intermediate in the silicone industry.

(1) Cosmetic field

Octamethylcyclotetrasiloxane is a common cosmetic raw material, often used to adjust the texture of products and improve lubricity.

(2) Pharmaceutical field

Octamethylcyclotetrasiloxane is used as an auxiliary solvent in some drugs to enhance the solubility and stability of drugs.

(3) Industrial field

Octamethylcyclotetrasiloxane can be used as a solvent, lubricant and surfactant, etc. It is widely used in industrial products such as coatings, adhesives and lubricants.

Packaging and Storage

Packaging, Storage and Transportation:

Packaging 1: 200Kg (iron drum/plastic drum);

Packaging 2: 950Kg (ton drum);

Packaging 3: tank truck (T22-TANK tank container)

Storage Conditions:

Store at 25°C or below in the original unopened container. The shelf life of this product is one year from the date of production. Expired products can only be used after passing the test.

For more information on Safety Data Sheets (MSDS), Product Safety Data Sheets, and Product Inspection Reports, please contact us.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...