If you are interested in our products or would like to learn more information, please contact us

|

CAS号 CAS No. |

2996-92-1 |

|

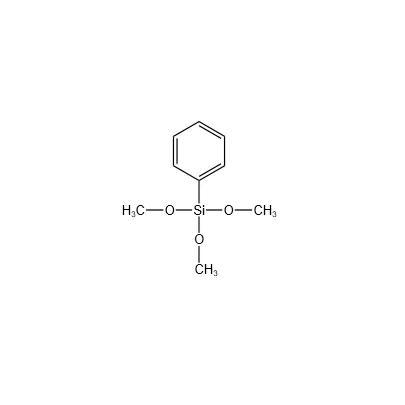

分子式 Molecular Formula |

C9H14O3Si |

|

分子量 Molecular Weight |

198.29 |

|

沸 点 Boiling Point |

233 °C |

|

闪 点 Flash Point |

94°C |

|

外 观 Color and Appearance |

无色透明液体 Colorless transparent liquid |

|

密 度 Related Density |

1.062 g/mL |

|

熔点/凝固点 Melting point/freezing point |

-25°C |

|

含 量 Min. Purity |

Min 98% |

Application:

1. Coupling Agent & Surface Treatment

Inorganic Filler Modification: Acts as a coupling agent for glass fiber, talc, kaolin, etc., significantly improving filler‑resin (epoxy, polyester, PP/PA) compatibility. Increases composite mechanical strength by 30%–50% and reduces water absorption by >40%, suitable for automotive parts, electronic housings, wind‑turbine blades, etc.

Substrate Surface Activation: Treats metal, glass, and ceramic surfaces to enhance coating/adhesive adhesion, improving corrosion resistance and durability.

2. Polymer Material Modification

Resin Modification: Modifies epoxy, phenolic, and polyurethane resins by introducing siloxane bonds and phenyl groups. Enhances heat resistance (service temperature >200 ℃), dielectric properties, and crack resistance for electronic packaging and high‑temperature coatings.

Rubber Modification: Serves as a cross‑linking agent for silicone rubber, improving tensile strength, tear strength, and extending the operating temperature range (–60 ℃ to 220 ℃). Suitable for aerospace seals, automotive damping parts, and medical silicone products.

3. Coatings & Adhesives

Coating Additive: Functions as an adhesion promoter and scratch‑resistance agent, improving weather resistance, chemical resistance, and hardness in industrial anti‑corrosion coatings, automotive coatings, and wood coatings.

Adhesive Modification: Enhances the bonding performance of PU/epoxy adhesives on difficult‑to‑bond substrates (plastics, ceramics), while improving high‑/low‑temperature resistance and aging resistance for electronic component bonding and construction structural adhesives.

4. Fine Chemicals & Advanced Materials

Silicone Synthesis: Used to produce methyl phenyl silicone resins and specialty silicone oils with excellent lubricity and radiation resistance for precision machinery lubrication and electronic insulating materials.

Pharmaceutical/Agrochemical Intermediates: Serves as a silicon‑based protecting group or nucleophile in drug synthesis and pesticide production.

Ceramic Matrix Composites: Acts as a ceramic precursor for high‑temperature (>1000 ℃) ceramic matrix composites in defense and aerospace engine applications.

Optical Materials: Used in synthesizing high‑refractive‑index optical resins and lens coatings, improving light transmittance (≥95%) and scratch resistance.

Packaging and Storage:

Product Shelf Life: 12 months

Packaging: Supplied in 200L iron drums or custom packaging (200L closed-head galvanized iron drums). Designed for moisture-proof and shock-resistant transport.

Storage: Keep container tightly sealed in a cool, dry place. Avoid direct sunlight and high-temperature environments.

Safety & Handling:

Due to its chemical nature, the product may react with other substances. Conduct thorough testing and evaluation before use.

Wear appropriate personal protective equipment (PPE) and follow relevant safety procedures during handling.

Avoid direct contact with skin and eyes. In case of contact, rinse immediately with plenty of water and seek medical attention promptly.

Special Note:

The product descriptions, technical specifications, usage recommendations, and related data provided above are compiled based on current scientific knowledge and experimental data, with professionalism and integrity. However, the actual performance of the product may vary due to uncontrollable factors such as transportation and storage conditions, external environments, supporting facilities, and user technical capabilities. Users must independently evaluate the suitability of the product for their intended applications. Before using the product, users should conduct sufficient testing to determine whether it meets their specific requirements.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...