If you are interested in our products or would like to learn more information, please contact us

|

CAS号 CAS No. |

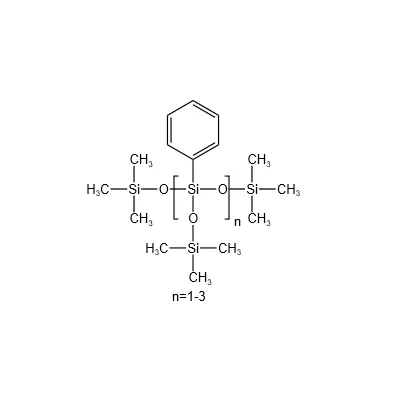

73559-47-4 |

|

粘度 Viscosity |

15~30 mm2/s (25°C) |

|

闭杯闪点 Closed cup flash point |

> 101℃ |

|

外 观 Color and Appearance |

无色液体 Colorless transparent liquid |

|

比重 Specific Gravity |

0.970-0.990 g/mL (25°C) |

|

折光率 Refractive Index |

1.4549-1.4626 (25°C) |

|

含 量 Min. Purity |

Min 99% |

Application:

1. High-end Electronics & Aerospace

High-voltage Electrical Insulation: Applied in coil impregnating varnish for Class H and above motors & high-voltage transformers, as well as satellite electronic component encapsulation. It raises equipment temperature resistance grade to 350℃ and extends insulation lifespan by over 5 times.

Aerospace Equipment Sealing: Used to formulate high-temperature-resistant sealants and greases for rocket engine components and spacecraft thermal control systems, withstanding extreme temperature variations from -80℃ to 350℃.

Electronic Component Heat Dissipation: Serves as the base material of high-end thermal greases (20%–30% addition level). It improves thermal conductivity, meeting the heat dissipation needs of 5G base stations and new energy vehicle power devices.

2. Food Contact & Cosmetics

Food Processing Equipment: Adopted as mold release agents for baking and lubricating greases for food machinery. It is non-migrating, odorless, and complies with food contact material safety standards.

Premium Cosmetics: Low-volatility grades are incorporated into hair care essential oils and anti-wrinkle creams (2%–8% addition level). It endows products with silky texture and long-lasting moisturization, featuring non-irritation.

Baby Products: Modifies silicone straws for baby bottles and pacifier materials, enhancing temperature resistance (-70℃ to 120℃) and flexibility with no migration of harmful substances.

3. Coatings & Composites

Extreme Environment Coatings: Added to industrial anti-corrosion paints and high-temperature equipment coatings, enabling coatings to resist temperatures from -50℃ to 300℃ with excellent weatherability, showing no chalking or cracking after 2000h accelerated aging.

Premium Composites: Modifies epoxy resins and carbon fiber composites, increasing material heat resistance from 180℃ to 300℃ and improving impact strength. Suitable for aerospace structural components and high-end medical devices.

Special Functional Coatings: Used to formulate radiation-resistant coatings for nuclear industry equipment surfaces, maintaining coating integrity and insulation performance.

4. Lubrication & Sealing

Wide-temperature Lubrication: Formulates high-temperature greases and gear oils for transmission parts of industrial kilns and bearings of deep refrigeration equipment. It retains excellent lubricity in a wide temperature range of -70℃ to 350℃, reducing wear rate by 60%.

Premium Seals: Modifies silicone rubber seals for deep-sea exploration equipment and high-temperature pipe joints. The seals are oil-resistant, temperature-resistant (-80℃ to 300℃) and minimize compression set.

Precision Instrument Protection: Acts as a protective coating for optical instruments and electronic sensors, providing insulation, moisture resistance and corrosion protection without affecting optical transmittance and sensor sensitivity.

Packaging and Storage:

Shelf Life: 12 months

Packaging: 200L steel drums or custom packaging (200L closed-top galvanized steel drums)

Transportation: Moisture-proof and shock-proof

Storage Requirements

Keep sealed and store in a cool, dry place. Avoid direct sunlight and high-temperature environments.

Usage Precautions

Due to its chemical properties, this product may react with other chemicals. Full testing and evaluation must be conducted prior to use.

Wear appropriate protective equipment and follow relevant safety operating procedures during application to avoid direct contact with skin and eyes. In case of accidental contact, rinse immediately with plenty of clean water and seek medical advice promptly.

Special Note

The above product descriptions, technical parameters, usage recommendations and related data are compiled based on current scientific knowledge and experimental data in accordance with the principles of professionalism and integrity. However, the actual performance of the product may vary due to uncontrollable factors such as transportation and storage conditions, external environments, supporting facilities and user technical capabilities. Users shall independently evaluate the product’s suitability for their intended application. Full experimental verification is required before use to confirm compliance with your specific requirements.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...