If you are interested in our products or would like to learn more information, please contact us

|

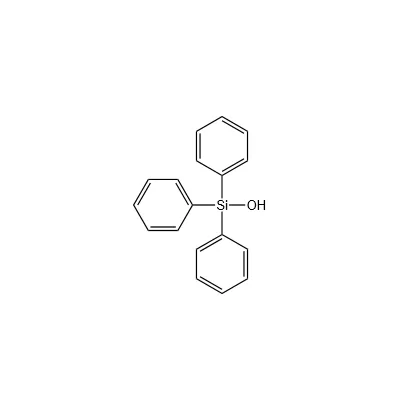

CAS号 CAS No. |

791-31-1 |

|

分子式 Molecular Formula |

C18H16OSi |

|

分子量 Molecular Weight |

276.41 |

|

熔点 melting point |

150-153 °C |

|

闪 点 Flash Point |

>200°C |

|

外 观 Color and Appearance |

白色固体粉末 White solid powder |

|

密 度 Related Density |

1.13 g/cm3 |

|

含 量 Min. Purity |

Min 99% |

Application:

I. Organic Synthesis Field

- Intermediate for organosilicon compound synthesis: As a core intermediate, it participates in the preparation of various high-end organosilicon derivatives. Its hydroxyl groups can undergo condensation, addition and other reactions with multiple functional groups, providing basic support for the synthesis of functional organosilicon materials with diverse structures.

- Catalyst/co-catalyst for organic reactions: Relying on its unique molecular structure, it can serve as a catalyst or co-catalyst for acid-catalyzed reactions, promoting transesterification, isomerization, cyclization and other reactions, improving reaction rate and target product yield. It is suitable for the synthesis process of fine chemical products.

- Ligand for transition metal catalysis: It can act as a ligand to form complexes with transition metals, regulating the electronic structure and spatial configuration of the metal center, thereby optimizing the activity and selectivity of the catalytic system. It is widely used in important organic synthesis reactions such as coupling reactions and hydrogenation reactions.

II. Electronic Information Field

- Sealing wax agent for electronic component packaging: Used in the packaging process of electronic components, it can enhance the interfacial bonding force between epoxy resin packaging materials and metal pins, improve the heat resistance of the packaging structure (heat resistance temperature up to 200℃), effectively reduce the risk of degumming in high-temperature environments, reduce the packaging defect rate, and ensure the stable operation of electronic components.

- Additive for semiconductor photoresist: As a functional additive in photoresist formulations, it can improve the wettability and coating uniformity of photosensitive materials, enhance the resolution and edge clarity of photolithographic patterns, and contribute to the miniaturization and high-precision manufacturing of semiconductor devices.

- Modifier for electronic thermal conductive materials: Used in the preparation of electronic-grade thermal conductive composites, it improves the compatibility between inorganic thermal conductive fillers (such as boron nitride, aluminum oxide) and organic matrices through surface modification, enhances the thermal conductivity and mechanical stability of materials, and adapts to the heat dissipation needs of high-end electronic equipment such as 5G base stations and new energy vehicle electronics.

III. New Energy Field

- Modifier for lithium-ion battery separator: As a key component of the lithium-ion battery separator coating, it can improve the high-temperature resistance of the separator, avoiding thermal runaway of the battery under high-temperature operating conditions; at the same time, it enhances the wettability of the separator to the electrolyte, improves ion conduction efficiency, and enhances the cycle stability and safety performance of the battery.

- Modification of sealing materials for new energy equipment: Used in the modification of sealing materials for new energy power generation equipment (such as photovoltaic, wind power), it improves the high and low temperature resistance, weather resistance and aging resistance of seals, ensures the sealing reliability of equipment in extreme environments, and extends the service life of equipment.

IV. Material Modification Field

- Modifier for organosilicon materials: Used in the modification of organosilicon materials such as high-temperature vulcanized (HTV) silicone rubber and room-temperature vulcanized (RTV) silicone rubber, it can improve the tensile strength, tear strength and elastic recovery rate of materials, while enhancing the radiation resistance and yellowing resistance of materials, expanding their applications in high-end fields such as aerospace and nuclear industry.

- Performance optimization of polymer materials: Used in the modification of polymer materials such as epoxy resin, polyurethane and polypropylene, it improves the heat resistance, flame retardancy and mechanical strength of materials by introducing phenyl and siloxane groups, improves the processing performance of materials, and adapts to the preparation needs of high-end engineering plastics and composites.

- Surface modification of inorganic fillers: It performs organic surface modification on inorganic fillers such as carbon fiber, fumed silica and glass fiber. Through the formation of stable chemical bonds between hydroxyl groups and hydroxyl groups on the filler surface, an organic coating layer is constructed, which significantly improves the compatibility and dispersibility between fillers and organic matrices, reduces the viscosity of the composite system, and improves processing efficiency and comprehensive product performance.

V. Special Coating and Protection Field

- Adhesion promoter for high-performance coatings: Added to high-performance coatings such as automotive electrophoretic paint and industrial anti-corrosion paint, it can improve the adhesion between the coating and metal substrates (such as aluminum alloy, steel), making the adhesion grade reach 5B; at the same time, it enhances the salt spray resistance and chemical corrosion resistance of the coating, extending the service life of the coating.

- Additive for extreme environment protective coatings: Used in extreme environment protective coatings such as outdoor architectural coatings and aerospace special coatings, relying on its hydrophobic, radiation-resistant, high and low temperature resistant properties, it improves the weather resistance and environmental adaptability of the coating, enabling the coating to maintain integrity and protective performance for a long time under harsh conditions.

VI. Fine Chemical and Other Fields

- Textile auxiliary: Used in the finishing process of textile fabrics, it can endow fabrics with water-repellent, oil-repellent, stain-resistant and other functions, while improving the softness and wear resistance of fabrics and enhancing the wearing performance of fabrics.

- Component of metal surface treatment agent: As an important component of silane treatment agent, it replaces the traditional phosphating process, forms an ultra-thin protective film on the metal surface, improves the corrosion resistance of metal, reduces the difficulty of wastewater treatment, and meets the needs of green and environmentally friendly industrial development.

Packaging and Storage:

Packaging Specifications

- 20kg vacuum-sealed paper drum (lined with double-layer PE bags + moisture-proof inner membrane)

- 50kg vacuum-sealed steel drum (lined with PE bag)

- 200kg vacuum-sealed steel drum

- Customized packaging solutions are available.

Storage Conditions

Store in a sealed, cool, dry and well-ventilated dedicated warehouse. Storage temperature ≤ 25℃, relative humidity ≤ 55%. Keep away from fire sources, heat sources, direct sunlight and humid environments; avoid co-storage with flammable, explosive and corrosive substances.

Transportation Requirements

Transport in accordance with ordinary chemical transportation standards. During transportation, take measures to prevent moisture, collision, sunlight and rain; it is strictly prohibited to transport together with dangerous chemicals. Handle with care during loading and unloading to avoid package damage and subsequent moisture absorption.

Usage Precautions

Due to the chemical properties of the product, it may react with other chemicals. Therefore, sufficient testing and evaluation must be conducted before use.

During use, wear appropriate protective equipment and abide by relevant safety operating procedures to avoid direct contact with skin and eyes. In case of accidental contact, rinse immediately with a large amount of clean water and seek medical attention as soon as possible.

Special Note

The above product descriptions, technical parameters, usage recommendations and related data are compiled based on current scientific knowledge and experimental data in line with the principles of professionalism and integrity. However, the actual product performance may vary due to uncontrollable factors including transportation and storage conditions, external environments, supporting facilities and user technical capabilities. Users shall independently evaluate the product’s suitability for their intended applications. Full experimental verification is required before use to confirm compliance with your specific requirements.

Ready to Get Started?

Contact Hocon Organic Silicon Product suppliers today to bring your idea or design to life sooner!

Please complete the contact form and we aim to get back to you within 24 hours.

Related Products

Our Market

Hocon International Co., Ltd. was established in 2015, is a manufacturer specializing in silicone products. Its product varieties include: organosilanes, silicone resin, silicone oil, modified silicone oil and their deep-processing products, the application fields of the products involve daily ...